Five stages of an IBR Inspection

Ensure full Indian Boiler Regulation (IBR) compliance with LRQA’s 5-step inspection process.

Streamline your Indian Boiler Regulations (IBR) certification journey with LRQA—the first third-party organization accredited as an IBR Inspecting Authority in India. With decades of global experience and recognition by the Central Boilers Board (CBB), LRQA provides end-to-end support across all five key inspection stages outlined under the IBR 1950 framework.

From design review and material certification to stage testing, welder qualification, and in-service inspections, our Competent Persons and technical experts work closely with you to ensure your boilers, components, and processes meet the stringent requirements of Indian regulations.

Whether you’re a manufacturer sourcing components globally, a boiler fabricator in India, or an operator seeking certificate renewal, LRQA helps eliminate bottlenecks, reduce delays, and achieve faster approvals with complete compliance—all while prioritizing safety, traceability, and operational excellence.

What is IBR Inspection?

IBR compliance is mandatory for manufacturers and suppliers of boilers and boiler components used in India. Every new boiler or associated equipment must be inspected and certified by an authorized Inspecting Authority through a Competent Person, either within or outside India.

LRQA provides complete IBR inspection services, from design review to in-service certificate renewal.

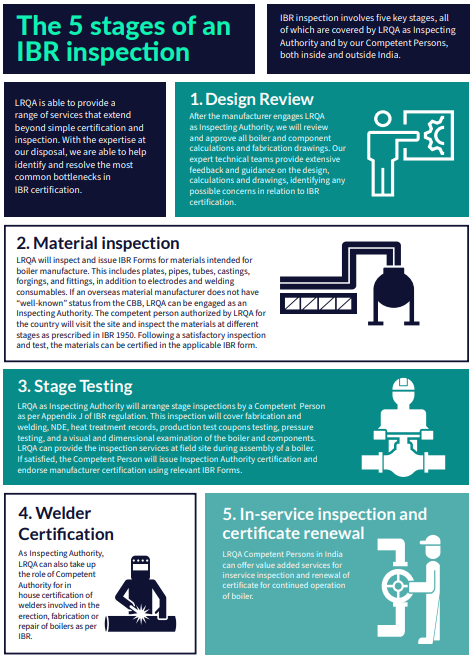

The 5 Key Stages of IBR Inspection

1. Design Review

Once LRQA is engaged, our team reviews and approves all boiler and component design calculations and fabrication drawings.

Our expert technical reviewers provide constructive feedback and identify compliance risks early—streamlining your path to IBR certification.

2. Material Inspection

LRQA issues IBR Forms for materials used in boiler manufacturing, including:

- Plates, pipes, tubes, castings, forgings, fittings, and electrodes

- Both “well-known” and other certified materials

Our Competent Person ensures that all materials conform to IBR requirements before they are approved for use in manufacturing.

3. Stage Testing

Stage-wise inspections are conducted by LRQA’s Competent Person and cover:

- Welding, fabrication, NDE, heat treatment records

- Hydrostatic tests, visual and dimensional checks

- Final inspection of the assembled boiler

Upon successful verification, LRQA certifies the equipment using applicable IBR forms.

4. Welder Certification

LRQA or its Competent Person assesses and certifies welders involved in boiler construction or repair.Certification is issued in accordance with IBR 1950 requirements to ensure safety and code compliance.

5. In-Service Inspection & Certificate Renewal

We also conduct periodic in-service inspections and handle certificate renewals, helping boiler owners maintain operational safety and IBR compliance.

Why Choose LRQA for IBR Inspection?

As a trusted IBR Inspecting Authority, LRQA offers:

- Faster approvals and expert guidance throughout the IBR lifecycle

- Seamless inspections across borders—ideal for global sourcing and manufacturing

- Decades of experience and a proven track record inside and outside India

- Assistance with design optimization, NDE interpretation, material traceability, and welder certification

- Training and technical support for your team

Ready to Get IBR Certified?

Partner with LRQA for expert-led inspections, faster approvals, and full compliance with Indian Boiler Regulations.

Our Guide: Indian Boiler Regulations

Download our free guide to understanding the Indian Boiler Regulations, which applies to most boilers and accessories sold in the country.

Our Guide: Indian Boiler Regulations